Description

1.The filling nozzle of the machine has anti-dripping function, which ensures filling accuracy.

2.Equipped with an intelligent eye, making the filling process more efficient.

3.With heat resistance function, can fill liquid that is about 100℃.

4.The inlet and outlet tube can be removed and replaced.

5.Microcomputer control system, the highest timing accuracy reaches 0.1 second.

Application

It can be used to fill low-viscosity liquid that is without particles, such as water, beverage, sauce,juice, soybean milk,toner,etc. The filling liquid must be without foam. This machine is small, which is an ideal choise for the small production.

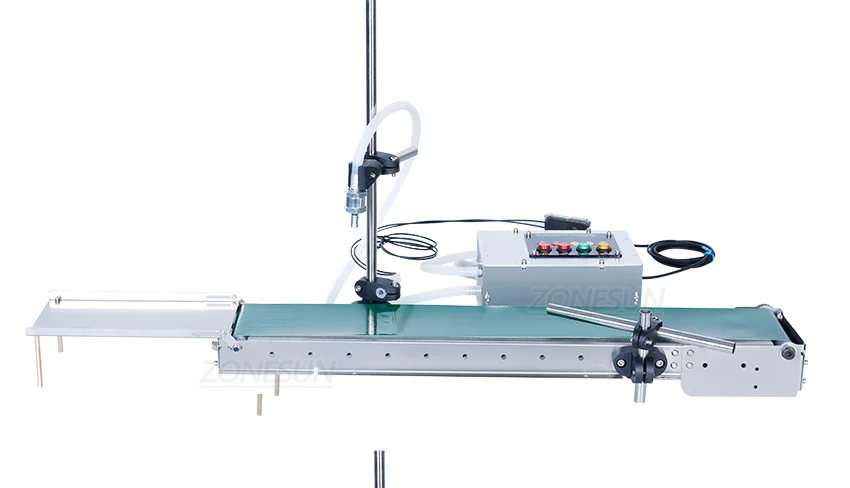

Conveyor installation and commissioning instructions

1.Insert the conveyor control cable,install copper columns and receiving tray,insert the U-shaped clip ,T-bracket and U-shaped clip ,tight the screws slowly to ensure that the bracket does not shake.

2.Install the support rod,bracket,prepare to connect the filling machine

3.Install the sensor,and inlet and outlet pipes,adjust the sensitivity of the sensor,the bottle will be filled automatically.

4.Adjust the water outlet to match the height of the bottle,comfirm the alignment of the water outlet and the bottle mouth form different angles.

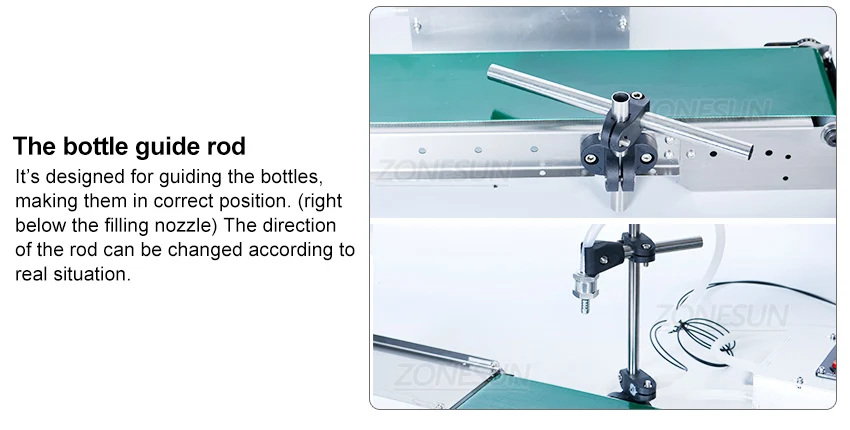

5.Adjust the bottle guide rod so that the bottle just passes the sensor.

6.Start-up trial operation,after adjustment,you can start working.

![JM_%11]1}@~J{HI5D$YJQGS](https://ae01.alicdn.com/kf/Hb6f3d0e491f4454aafe5da545f27f8424.jpg)